Design Options

What is the largest overhang I can have in my kitchen or laundry benchtop?

Without supports the largest overhang suitable for stone is 300mm. With supports that can be pushed to 450mm as long as the supports are every 600mm.

What is Vein Matching or Book Matching?

Vein matching is the process of cutting stone so that any veining or pattern in the material runs connected through both orientations of the surface. For example, from the top of an island bench down the waterfall panel. Book matching is the practice of mirroring a pattern in two pieces of material so that it gives the appearance of an open book. Both of these options are available in natural and engineered stone but contact our staff so that we can make sure material suitable for your project is available.

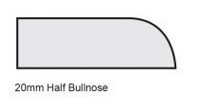

What is the difference between Edge Profiles?

Edge profiles significantly impact your benchtop’s performance, affecting everything from cleaning to safety. Since edges are the surface we come into contact with the most as we walk around and utilise the kitchen, the shape is essential for protecting and extending the life and performance of the stone benchtop.

See examples of the options available below.

What are the different sink types?

Undermount Sink - The sink sits underneath the stone, with the exposed stone edges polished

Drop-in Sink - The sink sits above the stone

Butlers Sink - these sinks display an apron front and sit above your cabinetry

How much clearance is required from my cooktop to my stone splashback?

For both electric and induction cooktops it is a requirement to have a minimum 50mm gap from the edge of the cooktop to the splashback. For gas cooktops the minimum requirement is 200mm from the periphery of the gas burner to the splashback.

Can stone be curved?

Modern design is shifting toward curved forms in both interior and exterior surfaces. We are able to craft curved panels using either faceting methods in the case of natural stone or thermoforming in the case of mineral surface products.

Facetting involves glueing strips cut on an angle into a curve to form the rough shape required. That piece is then placed onto a CNC to be shaped, removing excess material till the bulk of the work is done. The final finish is achieved by hand, working to smooth out the face and then either hone or polish to completion.

Thermoforming involves milling the material to between 3 and 6mm thick before using heat to curve the stone to the desired shape.

In planning out projects involving curved forms it is important to reach out and ask the question as to what is possible and what is not. This could be in terms of material choice, for example curving softer material like marble is much easier and more achievable than using a hard material like quartzite or granite. In terms of thermoforming mineral surfaces a general rule is that colours which have a higher level of large aggregate present do not curve well, whereas veined colours or plain colours are suitable for the process. It could also be in terms of how tight a radius is able to be achieved or how to create multiple shapes that make up your design.

Please note that printed porcelain or sintered stone surfaces cannot be curved.